Macrotech Steels

Expanding Our Professional Horizons

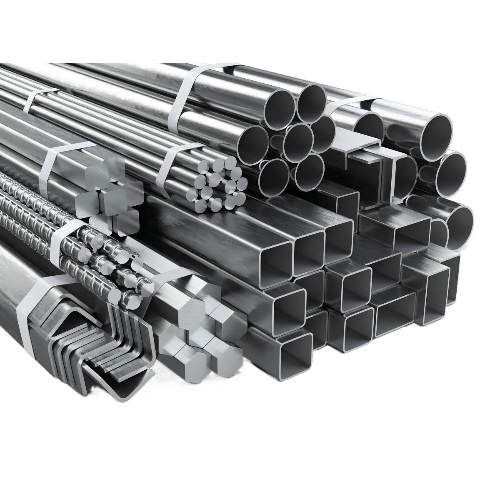

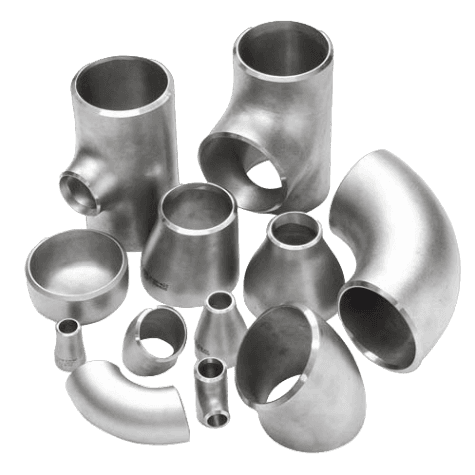

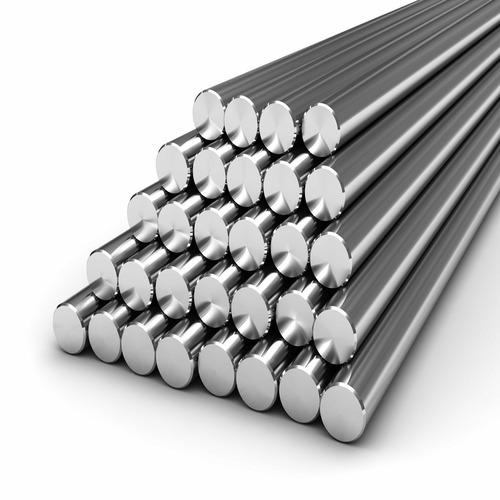

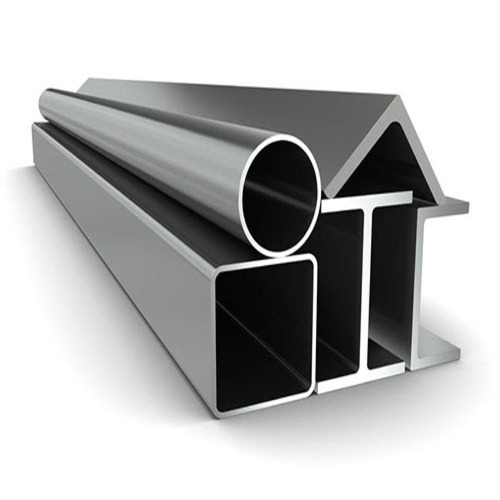

One of the leading Importers, Exporters, Stockist & Suppliers of Ferrous and Non-Ferrous Metal in form of Stainless Steel Bars, Wires, Pipes, Sheets, Coils, Plates, Forged and Pipe fittings. Having an experience of more than one decade in this field makes us leading exporters and domestic suppliers. Most of our clients are Government and Public sector companies like Chemical, Thermal Power, Nuclear Power, Heat Exchanger etc.

Macrotech Seamless & ERW Pipes

Stainless Steel: ASTM A312 TP 304/ 304L/ 304H/ 316/ 316L/ 317/ 317L/ 321/310/ 347/ 904L etc.

Carbon Steel: ASTM A53 GR. B/ A106 GR. B/ API 5L GRADE B/ API 5L GR.X42/46/52/56/ 60/65/70/ A333 GR. 3/ GR. 6, etc.

Alloy Steel: ASTM A335 GR. P1/ P5/ P9/ P11/ P22/ P91, etc.

Type: Round pipe, Square Pipe, Rectangular Pipe, Oval Pipe, Half Round Pipe, etc.

Value Added Services

Internally and externally polished tube is ideal for the dairy, food & beverageiIndustries where highest degree of purity and cleanliness is essential, with this process we can achieve the required surface finish after mechanical polishing, we can further improve for Bio Pharma industries by Electro polishing.

Macrotech Sheets & Plates

Material Grade : Stainless Steel, Nickel Alloys, Carbon Steel, Alloy Steel, Copper, Brass, Aluminium, Cu-Ni etc. IBR Non IBR.

Grades : 904G, 309S, 310HG, 316TiG, 317L, 317LNG, 321, 321H, 405, 410, 410S, 429G, 430, 439, 409L.

Duplex & Super Duplex : S31803, S32750, S32760

Stainless Steel Sheets & Plates as per ASTM A 240 Gr. TP 304, 304L, 304H, 304LH, 309, 309S, 309H, 310S, 310H, 316, 316L, 316H, 316LN, 316Ti, 317, 317L, 321, 321H, 347, 347H, 348, 348H, 409, 410, 420, 430, 904L.

Alloy steel Plates as per ASTM A 387 Gr.2,5,9,11,12&22in class 1 & 2; ASTM A 204 Gr. A & B, DIN 17175 Gr. 15Mo3 & 16M03 with IBR Test Certificate..

Carbon Steel / Boiler Quality Plates as per IS 2062 Gr. A, B & C, IS 2002 Gr. 1 & 2, ASTM A 516 Gr. 60 & 70, ASTM A 515 Gr. 70.

Others : Monel, Nickel, Inconel, Hastalloy, Copper, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminium, High Speed Steel, Zinc, Lead, etc.

FORMULA Weight of S.S. Sheets & Plates Length (Mtrs) x Width (Mtrs.) x Thick (mm) x 8 = Kg. Per Sheet Lenght (Ft) x Width (Ft) x Thick (mm) x 3/4 = Kg. Per Sheet